Micro 3D Printing Services | DLP

Empire Group's Micro DLP Solutions: Unleash Micro-Precision for Complex Parts.

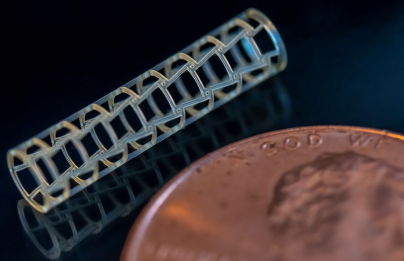

Miniaturized components are increasingly popular in many applications across a range of industries. From medical devices to defense electronics, many systems now rely on very small components, and micro 3D printing is essential in their manufacture.

Micro DLP printing technology produces parts with high resolution and superior efficiency. Learn more about Empire Group’s micro 3D printing services.

Micro 3D Printing Capabilities

At Empire Group, we offer micro DLP printing for microfabrication. Micro DLP printing is the smallest scale 3D printing process and has facilitated significant advancements in the development of many types of microelectronic components. Applications in microfluidics, medical devices, electronics, and other industries benefit from this process's high levels of accuracy, precision, and resolution with every print. Micro DLP is ideal for intricate 3D geometries with very tight tolerances.

Micro 3D Printing Specs

The following are some of the specifications of our micro DLP printer technology:

- Machine: BMF S240

- Build Size: 100x100x75 mm

- Optical Resolution: 10 micron

- Surface Finish: 0.4-0.8µm Ra (top), 1.5-2.5µm Ra (side)

Material Options

Depending on our customers' needs, we use different types of micro DLP 3D printing materials, including:

-

HTL Resin

This material offers superior heat resistance, rigidity, and strength, with the ability to hold up in environments up to 140 °C. HTL resin is suitable for sterilization, ideal for medical applications and other high-resolution uses.

-

BIO Resin

Non-implantable medical devices of all types may depend on this biocompatible resin material. To meet the needs of these types of environments, the material is ISO 10993 certified according to biocompatibility tests for toxicity, skin irritation, pyrogenicity, cytotoxicity, and more.

-

RG Resin

This is another biocompatible resin that provides optimal durability for end-use applications. One added benefit of this material is its waterproof nature, making it ideal for use in medical snappers, devices, and electrical applications.

Main Benefits of Micro DLP 3D Printing

Micro-scale 3D printing offers certain advantages that make this process preferable to other fabrication methods:

Industrial Applications of Micro 3D Printing

Many industries today use miniaturization to make their products smaller and more convenient without compromising quality. Micro 3D prints achieve miniaturization goals for applications in industries such as:

- Electronics

- Robotics

- Microfluidics

- Medical Devices

- Optics

- MEMs

- Life Sciences

The Micro DLP Experts: Why Partner With Empire Group

For over 20 years, Empire Group has developed into a specialist in prototyping and low-volume production, with customers in many mission-critical sectors from medical and electronics to defense and aerospace. Our DLP additive manufacturing services give our customers top-quality micro 3D prints for individual components and end products.

To maintain consistently high quality across our production processes, we are certified by ISO 9001:2015, ISO 27001:2013, and ITAR. In addition to micro 3D printing services, we also offer stereolithography (SLA), multi-jet fusion (MJF), and fused deposition modeling (FDM). Our vast range of material capabilities ensures you have the parts and products that fit your exact parameters. In the process, we work to stay within your budget and time constraints.

Micro 3D Printing Blogs

- Micro 3D Printing Produces Higher Performing Parts Faster & at a Lower Cost

- 5 Ways Micro 3D Printing is a Manufacturing Game-Changer

- Prototyping Electronic Components With Micro DLP

- The Future of Micro 3DP for Medical Devices

Whitepapers

- Making the Case for Micro-Precision 3D Printing

- Introduction to 3D Printing with Micro DLP

- SLA vs DLP vs Micro DLP

Want to Know if Micro 3D Printing Would Work for Your Project? Contact Us Today!

Want to take advantage of micro 3D DLP printing for your application? Our experts are ready to discuss your next project and get started on your design. To learn more about our services, contact us today. To get started on a custom solution, request a quote.