Industrial 3D Printing Service • Prototypes to Final Parts

Fast, Accurate, and Affordable 3D Printed Parts

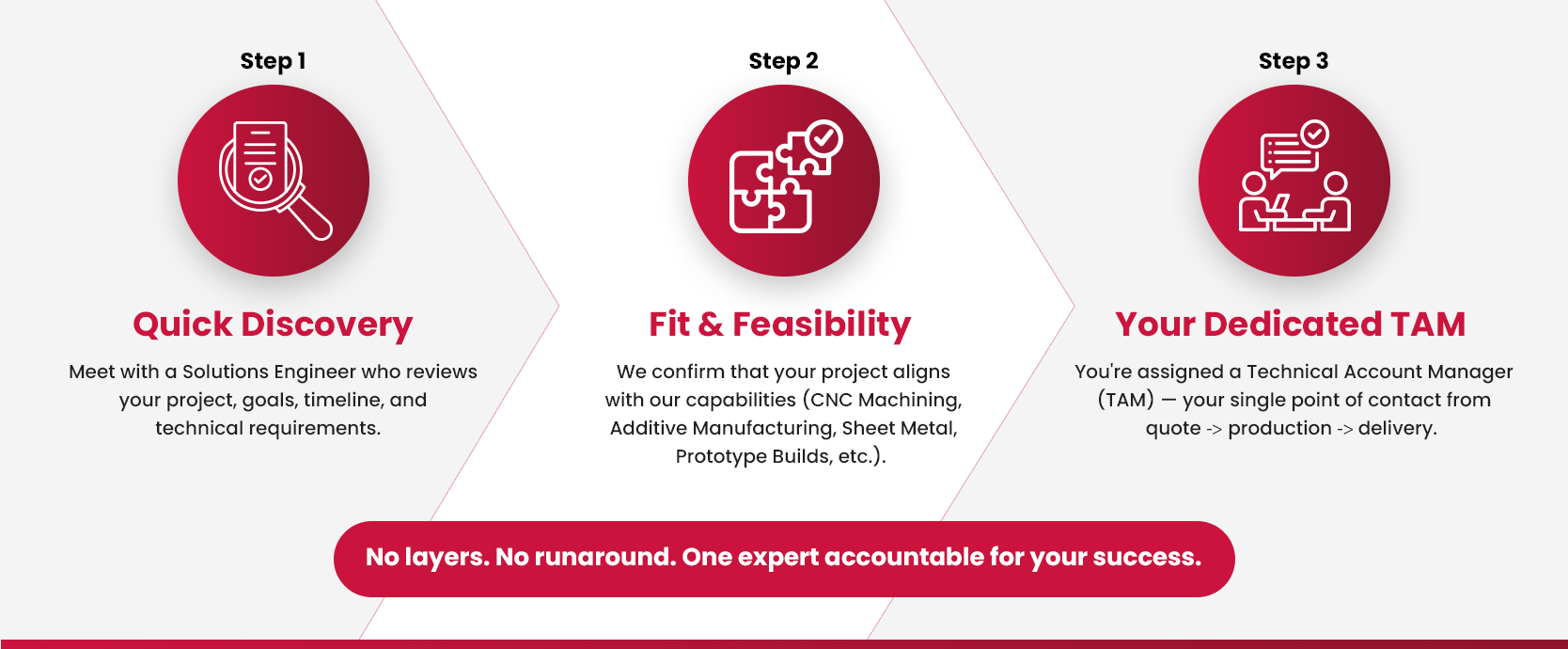

Our Process

End-to-End 3D Printing Solutions

As an additive manufacturing method, 3D printing builds a part layer by layer from materials like plastics, resins, powders, metals, and more to achieve a component in a desired shape. The process is compatible with prototyping as well as low-volume production, generating parts in complex configurations that may be difficult to make using traditional manufacturing methods. Allowing for rapid design iterations, 3D printing enables you to decrease your time to market without sacrificing quality. It's also beneficial for its reductions in material waste and tooling costs.

Empire Group USA, Inc.'s professional 3D printing services ensure effective, turnkey solutions for precision products and detailed designs. Experienced in working with a broad spectrum of materials and multiple 3D printing techniques, our team works closely with our clients to select the best combination of materials and production methods to deliver high-quality results and optimal versatility while helping you decrease turn times.

Whether it’s an initial prototype or your final end-use parts, we utilize cost-effective 3D printing to transform the way new products are brought to market.

3D Printing Processes & Materials

Fused Deposition Modeling (FDM)

A unique powder based 3D printing process that enables us to print high strength, low cost parts.

This process is great for low-volume production of end-use parts

With this technology, parts will have mechanical properties that rival those of injection-molded parts

We recommend this process for complex part geometries or parts requiring specific production-grade materials

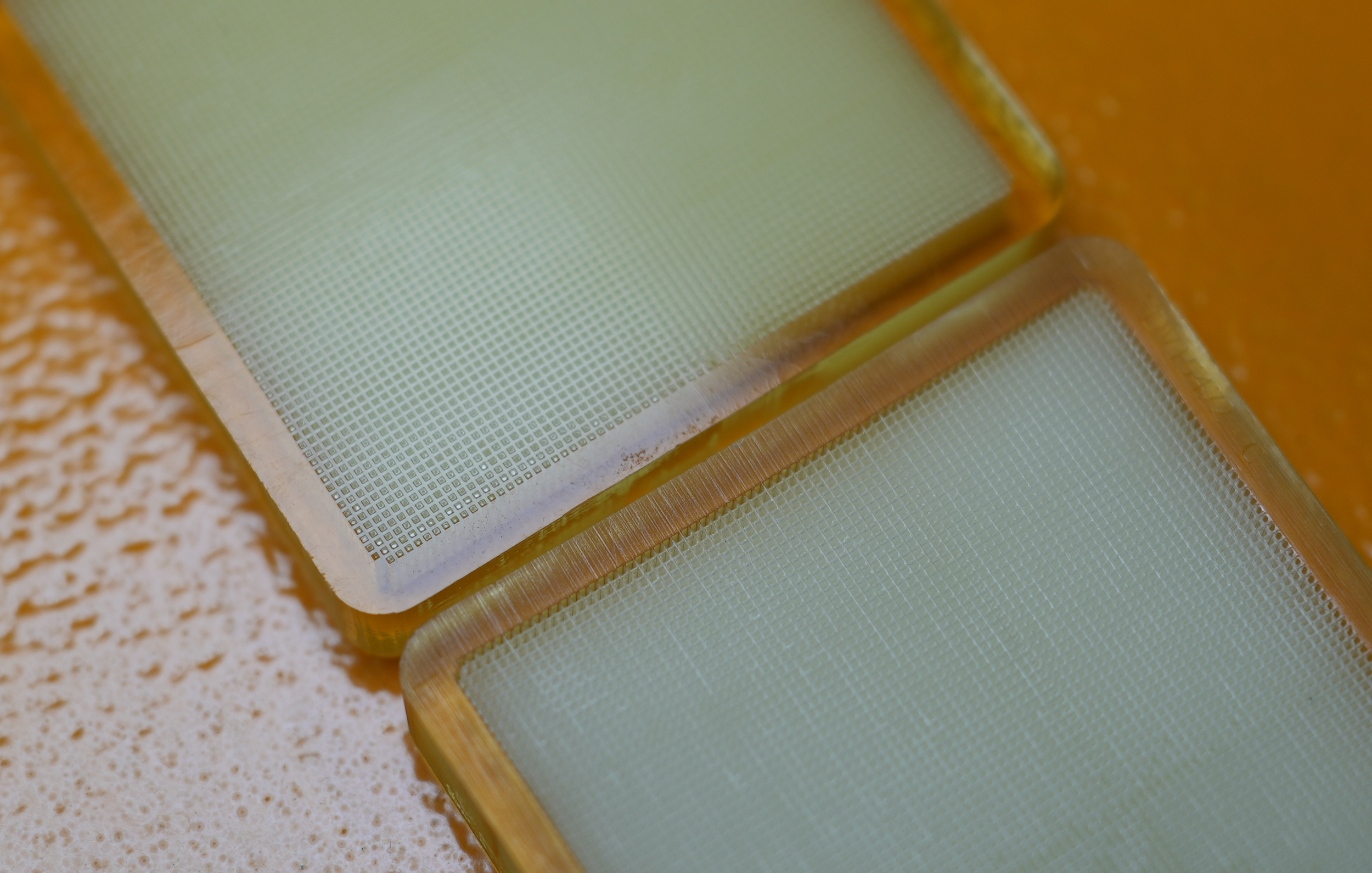

SLA uses resin to produce parts with outstanding surface smoothness and edge definition.

SLA is great for clear or opaque parts with a high level of detail and accuracy

When you need realistic, high-end aesthetic models, this is the process we’ll typically use

This technology can print with quicker turnaround times compared to other printing methods

We use this process for very large parts.

Fused Deposition Modeling (FDM)

FDM enables quick iterations of large scale models at a low cost.

This process is great for printing large-scale models

We offer FDM in a wide variety of materials and can help you select which is best for your project

We typically use this process for low resolution or for proof of concept models

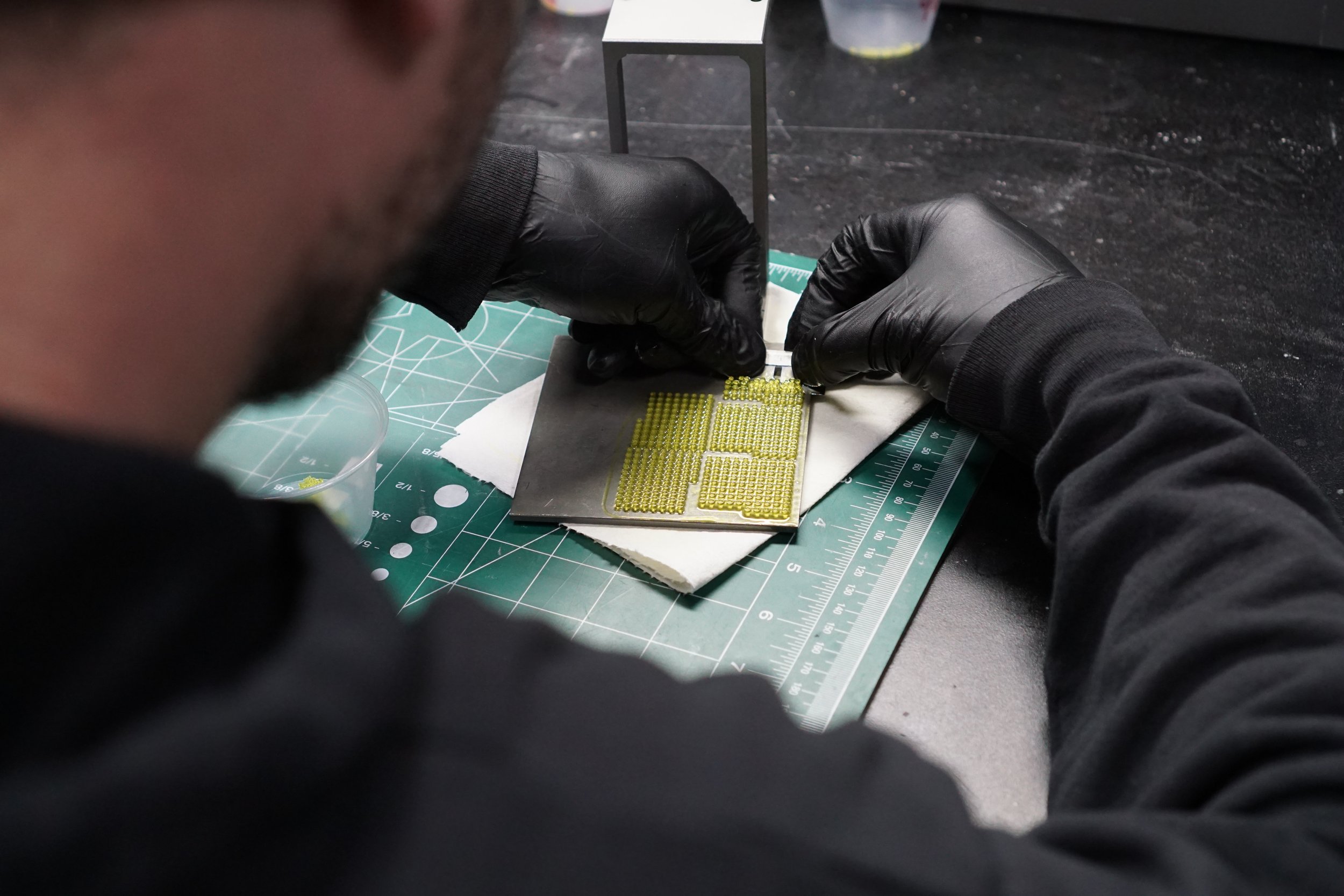

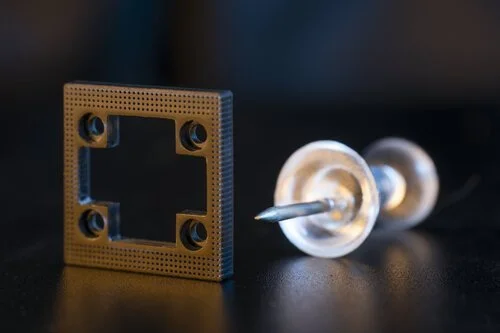

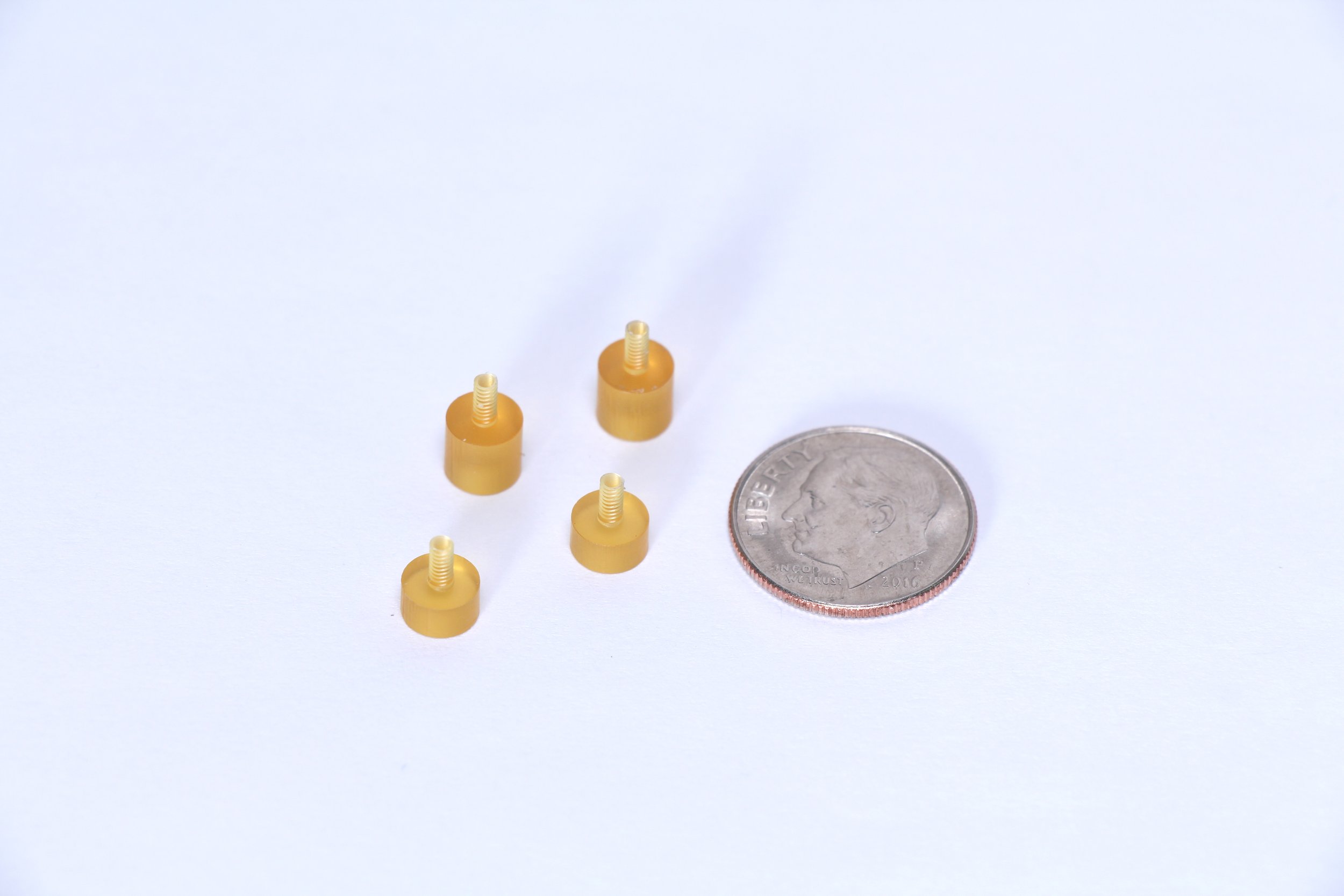

Micro 3D Printing

Micro DLP is the only industrial 3D printing technology that matches or exceeds the quality of high-resolution micro injection molding at a significantly lower cost.

We use this process when you need ultra precise parts printed at a micro level

Biocompatible materials allow parts to be used for medical research and development

Offer a larger build volume ideal for industrial manufacturing and prototyping

3D Printing Applications:

Rapid Prototyping

An iterative design process that employs 3D printing to fabricate scale models of real parts or product assemblies quickly. This method of prototyping facilitates an agile product development approach that is cost-effective and can drastically reduce the time spent in the design and engineering phase.

Additive Manufacturing

AM is 3D printing applied to the manufacturing process as a cost-effective solution for producing low volume products and end-use parts. With AM, you can achieve unequaled design freedom, shorter lead times, and a streamlined supply chain. AM makes it possible to accelerate production and gain a competitive edge in the market.

Industries We Serve:

Why Work With Empire Group?

Based in Southeastern Massachusetts, Empire Group has spent over two decades building a strong reputation as a trusted partner for clients along the East Coast and across the nation. We specialize in prototyping and low-volume manufacturing for mission-critical applications in sectors ranging from aerospace to automotive.

At Empire Group, supporting product development is not just a service — it's part of our DNA. Our dedicated team, the heart of our success, is passionate about driving growth and ensuring 100% customer satisfaction. Committed to quality and security, we're an ITAR-registered company holding ISO 9001 and ISO 27001 certifications. It's our goal to offer the best 3D printing services possible in-house from stereolithography to FDM 3D printing for quality components that give our clients a competitive edge.

Our advanced 3D printing technologies ensure precision, able to achieve even the most intricate details in your final products. From realistic prototypes and 3D printing models for proof of concept applications to high-resolution printed end products, we aim to meet the needs of both your budget and your project's time frame. Empire Group emphasizes affordability and efficiency in our 3D printing services, with lead times as short as 72 hours for prototypes and production.

Contact Our 3D Printing Experts Today!

Empire Group combines high-tech, innovative manufacturing methods with an expert team to deliver full customer satisfaction on even the most challenging of projects. Our service capabilities support clients throughout the entire product development journey, eliminating the need to partner with multiple service providers. In addition to 3D printing and prototyping, we also offer design and engineering, CNC machining, casting, finishing treatments, assembly, and more to provide comprehensive product and production solutions for our clients.

To partner with a full-service product development group for affordable 3D printing services, we invite you to contact our team for more information or request a quote today.

Related Content