Medical Device Prototyping Solutions

High-Quality, Cost-Effective Prototyping for Critical Medical Applications

Empire Group delivers innovative and precise medical device prototyping with unmatched speed. From initial ideas to polished prototypes, we empower medical manufacturers to move faster. Our complete in-house services are engineered to cut costs, boost quality, and shorten your time to market.

Why Choose Empire Group for Medical Device Prototyping?

-

Faster FDA Validation & Market Entry

Rapid iterations and design testing help accelerate product development and compliance. -

Design & Engineering Support

We apply DFAM (Design for Additive Manufacturing) to optimize performance and manufacturability from day one. -

Precision Manufacturing, In-House

From micro 3D printing to full-scale CNC machining, we deliver high-tolerance parts fast. -

Medical-Grade Materials & Finishes

Silicone, urethane, resin, epoxy, and more—plus custom surface treatments and functional assembly. -

Certified for Quality & Security

ISO 9001 • ISO 27001 • ITAR Registered

Our Medical Device Prototyping Capabilities

Design & DFAM Consultation

We review your design for material efficiency, structural performance, and additive manufacturing feasibility.

3D Printing

Perfect for detailed, high-precision parts, especially with our Micro DLP process for microfabrication needs.

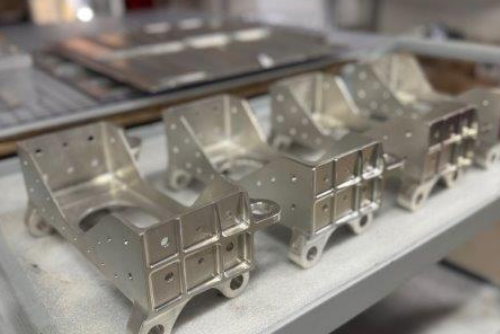

CNC Machining

Fast and accurate for looks-like and works-like models with tight tolerances and real-world functionality.

RTV Casting

An economical method for complex, production-quality prototypes using medical-grade materials.

Custom Finishing & Assembly

From painting and polishing to full hardware integration, we’ll deliver polished, presentation-ready prototypes.

Start Your Medical Prototyping Project Today! Contact Us

Ready to transform your medical device ideas into reality? Fill out the form below to connect with our specialists and get started.