Why 3D Product Renders Are So Valuable For Product (and Business) Development

Innovative rapid manufacturing technologies are dramatically expanding the prototyping capabilities available to product development teams. Today, design engineers can use 3D printing to quickly fabricate early-stage “look and feel” prototypes before leveraging rapid injection molding to create later-stage prototypes using final production materials (ideal for regulatory and market testing). These capabilities can unlock a new level of value from prototypes, and in many cases dramatically accelerate the product development process.

But physical prototypes are only one important resource for product development teams to consider. In this blog, we explain why 3D digital product renders are an important part of the portfolio of options available today.

3D Product RENDERS Can Offer Outstanding Value for Business Development

If prototypes help bridge the gap between product ideation and physical production, digital product renders extend this bridge to business development scenarios where physical prototypes are not:

1. Cost effective. For example, bringing an early-stage product concept demonstration to a trade show might be important for exploratory business development discussions. But the cost of fabricating a physical prototype may not make sense for a product in these earliest stages of market research.

2. Physically convenient. For large, heavy, or fragile products, bringing a prototype to a trade show or sales discussion may be unnecessarily costly and burdensome (if not outright impossible). Scaled down physical models are one possibility, but renders offer an even faster and more cost-effective alternative.

3. Sufficiently agile. If a business development professional gets an urgent request to engage in a detailed exploratory discussion halfway across the globe, physical models simply may not be fast enough. Digital renders can be generated quickly, readily customized to specific clients or opportunities, and instantly sent anywhere in the world.

4. Sustainable. By using 3D modeling to review multiple design possibilities, companies can achieve the sustainability requirements for their products. The number of physical prototypes can be reduced, greatly reducing material waste.

In the post COVID-era, more and more business development is occurring in a purely digital context, and we only expect adoption of 3D models to accelerate. This trend is not just a stopgap measure. High-quality 3D renders can capture physical product characteristics at an extraordinary level of detail. In many cases, they are not simply an economical alternative, but the best way to provide clients, partners, or prospects with the most information-rich product model possible. For example, with complex manufacturing, automotive or aerospace equipment, 3D renders are often a much better option than scaled-down models for demonstrating intricate and/or internal design features.

Using Modeling to Move from Concept to Design: 3D Modeling in Product Development

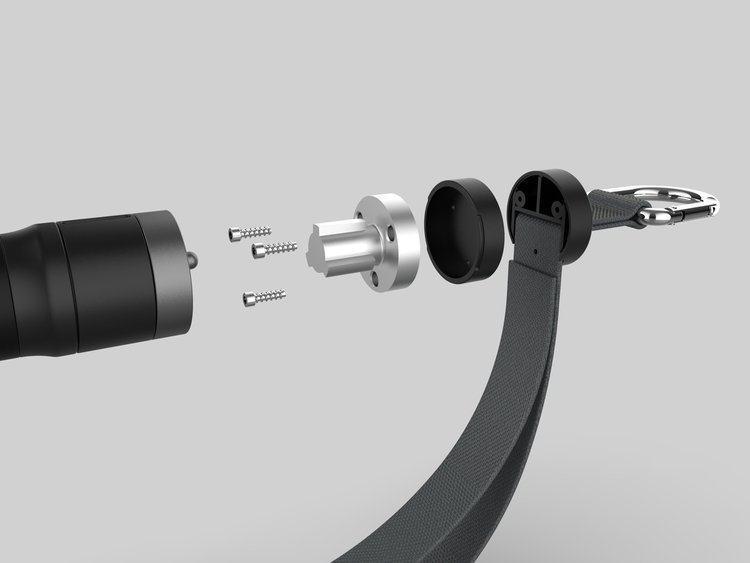

High-quality 3D renders are also valuable for the product development process itself. When moving from an initial list of proposed features to ideation for actual design concepts, 3D models are the best way to start conceptualizing the physical forms the product can take. In the early stages of exploring and refining multiple design concepts, 3D renders are often the perfect tool—they can be generated quickly, modified almost instantaneously, and readily shared between business units, distributed teams, and external vendors.

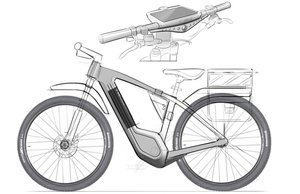

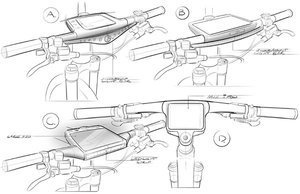

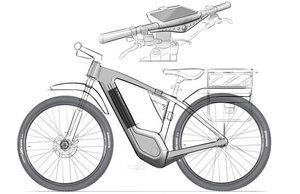

Empire Group offers high-touch, end-to-end product development support, and we see our ability to provide high-quality 3D digital modeling as a crucial aspect of our service offerings. Even with our ability to bring unprecedently flexible physical prototyping technologies to the table, the generation of 3D digital models remains instrumental to virtually every product development process we support. For a look at some of our renders in the context of an actual product development process, our case study here shows the evolution from concept sketches to photorealistic digital rendering for a tactical police bicycle.

When our product development team engages with a new project, initial data-gathering occurs in a discovery phase which includes:

Market Research & Competitive Analysis

Human Factor & Ergonomics Studies

Color Studies

Idea Generation

Patent Assessment and Application

As the project moves from initial discovery to the design phase, 3D modeling plays a crucial role in transitioning from concept to physical design. Important related resources provided by our team include:

Concept Sketches

Form Development

3D CAD Models

2D & 3D Digital Renderings

Animations

Patent Drawings

The timely generation of these resources can be incredibly important to the product development process. Doing so requires a holistic skillset including visual art, engineering, and behavioral science. Retaining this skillset in-house can be costly, which is precisely why a full-service product development team can be so valuable. At Empire Group, our industrial design team collaborates closely with industrial engineers to hone in on a product vision that solves technical challenges without sacrificing user experience, aesthetics or manufacturability.