Custom Trade Show Models & Sales Samples

Your Vision, Our Models: Discover Innovative Trade Show Models for Your Brand

At Empire, one of the services we take great pride in is our ability to create cutting-edge, brand-specific trade show models and sales samples. While most competitors may offer 3D printing or CNC machining for parts, Empire does it all under one roof. Our capabilities were designed for this very purpose back in 1999, and our name reflects our long-standing legacy of creating models for iconic brands, like Star Wars.

Our Process: How We Build High-Quality Trade Show Models

Below, we’re excited to showcase how we leveraged our technology and expert team to help PTC tell their story and demonstrate the power of what they can do for you. We’ll also briefly walk you through the process of how these models come to life.

Step 1:Design for Additive Manufacturing (DFAM)

Step 1:Design for Additive Manufacturing (DFAM)

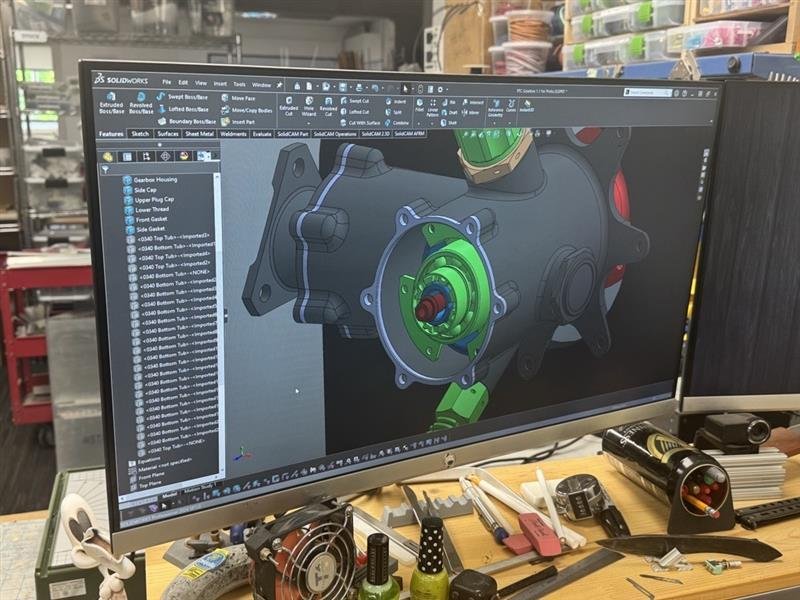

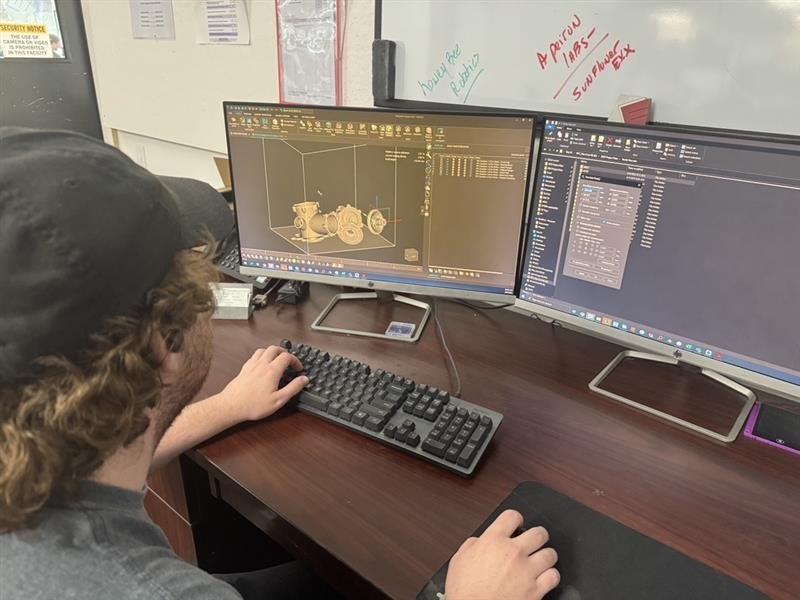

Step 1:Design for Additive Manufacturing (DFAM)We begin with the CAD of the product, which is often reverse-engineered to ensure optimal design for 3D printing. This step, known as DFAM, helps us ensure that the model is not only functional but also maximizes the potential of additive manufacturing technologies.

Step 2:Technology Selection

Step 2:Technology Selection

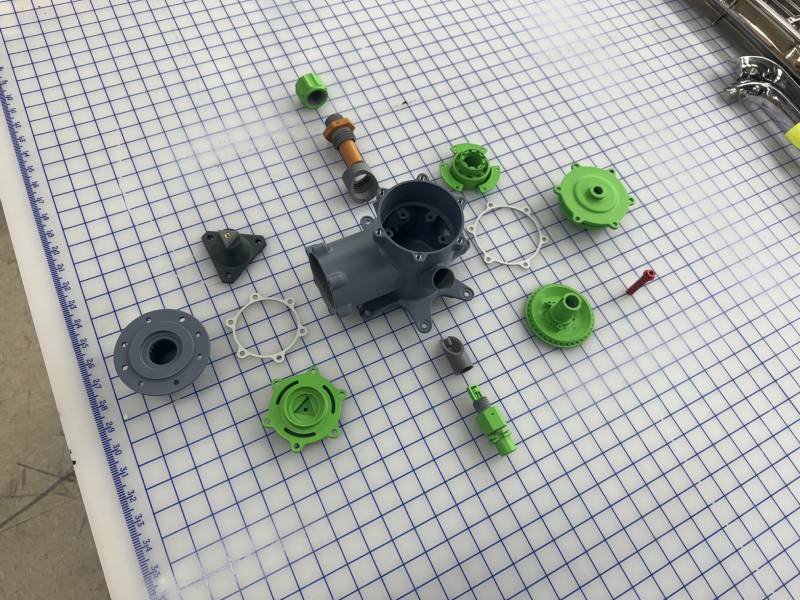

Step 2:Technology SelectionThe next step is determining the best technology for the application. For these models, we chose HP Multi Jet Fusion (MJF) printing, one of our favorites. MJF allows us to print in nearly indestructible Nylon PA12 material, which is ideal for producing robust, high-performance parts.

Step 3:Finishing Touches

Step 3:Finishing Touches

Step 3:Finishing TouchesOnce the parts are fully printed, our talented finishing team takes over. We use a proprietary process to coat and finish the parts, achieving a high level of visual and functional quality. This step ensures the models look stunning and are durable enough for the rigors of a trade show.

Step 4:Final Assembly and Quality Control

Step 4:Final Assembly and Quality Control

Step 4:Final Assembly and Quality ControlThe final steps include fitting and assembling the parts, followed by a thorough quality control inspection. Only after passing this rigorous check do the models head out the door, ready to impress at trade shows like the one in Paris.

.png)